Creating the perfect heating environment.

Elevate Your Greenhouse Experience with Niagrow: Pioneers in Precision Heating Solutions and Climate Control

Experience professional-grade greenhouse heating solutions with Niagrow. From inception to success, our dedicated team ensures precision and unmatched comfort. Trust us for tailored heating systems that redefine excellence. Your journey to greenhouse climate control. Ready to transform your greenhouse climate control? Your journey starts here. Contact us today for a consultation and take the first step towards optimal heating solutions.

Error message

- Notice: Undefined offset: 0 in include() (line 23 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

- Notice: Undefined offset: 0 in include() (line 25 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

- Notice: Undefined offset: 0 in include() (line 56 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

- Notice: Undefined offset: 1 in include() (line 23 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

- Notice: Undefined offset: 1 in include() (line 25 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

- Notice: Undefined offset: 1 in include() (line 56 of /home/ggsgreen/public_html/sites/all/themes/Porto/templates/node/node--twitter-feed.tpl.php).

Heating for Large Scale Commercial Greenhouses

Plants need water, sunlight, and fertile soil to grow, but they also need ideal temperature conditions to avoid freezing. With the right commercial greenhouse heating solutions from GGS Structures Inc., you can maximize growth and ensure strong and healthy crops throughout the year. Which heating system is right for your operation? There are several to choose from, each offering a variety of potential benefits...

Biomass

Heating your greenhouse is non-negotiable, but that doesn’t mean you lack choices when it comes to how you heat. These days, many commercial greenhouse heating systems include more than one option, so even if you currently rely on a gas or oil system, you can utilize a modern wood heating equipment to supplement and perhaps eventually supplant older systems.

With innovative technologies, including advanced controls and safety considerations, these fully-automatic biomass systems offer an efficient, economical, and sustainable option that delivers carbon neutral operation. Plus, you can choose from fuel sources, including pellets, sawdust, woodchips, and mixed woods, depending on your preference. This high-efficiency system can save you over fossil fuels and help you do your part for the environment.

Forcas Pipe

When it comes to heating your greenhouse, you can opt for ambient or more direct heating methods, or a combination of the two. If you’re looking for effective and affordable solutions, a forcas pipe system can deliver heat close to crops, minimizing waste while ensuring your plants receive sufficient heating to maintain optimal growth conditions.

This lightweight and practical system consists of thin wall steel tubing that has been hot-dipped with galvanized coating to protect against corrosion. With a narrow diameter of just 28/35mm, this piping significantly reduces required water volume and provides heating where it is needed most with speed and efficiency, saving you money.

In-Floor Heating

In-floor heating is one of the most efficient and effective commercial greenhouse heating solutions for a couple of reasons. First, heat rises, so providing a heat source at the lowest level ensures optimal ambient heating for a structure.

In addition, concrete flooring typically radiates the cool ground temperatures of the soil it sits on, counteracting other heating sources. You won’t have this problem with in-floor heating, which combats this common form of heat loss.

Unobtrusive heating elements are hidden out of sight beneath flooring, and if you have flood floors, you’re crops will benefit from both warm flooring and warm irrigation water, allowing for multi-purpose temperature control that facilitates healthy crops.

Overhead Heating

Most greenhouses will not use overhead heating as their primary heat source, since solutions that are closer to the plants are more effective. However, overhead heating systems are essential as a supplemental heat source in climates that experience cold temperature seasonally, overnight, or both. When you need to protect your crops from top to bottom in cold weather conditions, having a heat source above to supplement others systems is ideal.

In addition, you can choose a system with snow melt protection to prevent buildup of snow on the top of the greenhouse that could impact interior temperatures and potentially compromise the integrity of your structure. Overhead heating also allows you to maximize your greenhouse space by incorporating hanging baskets to increase usable square footage for crop growth.

Perimeter Heating

If outdoor temperatures in your climate are relatively stable year-round, you may not feel like you need a perimeter heating system, but in regions that experience low temperatures at night, seasonally, or both, commercial greenhouse heating systems that address the perimeter of the structure are critical to protecting crops. These heating systems supplement other heat sources throughout your structure to regulate the interior environment and protect crops from exterior temperature fluctuations.

What if you don’t need perimeter heating during daytime hours, or you only need it seasonally? You have the option to control this heat source with separate zone controls, or integrate it with your existing heating system, depending on your needs. With sidewall heating, you’ll keep exterior temperatures from impacting your crops.

Under-Bench Heating

Some grow houses place planters on flooring or use flood floor setups. Others elevate crops on benches or tables. This may depend on the crops you’re growing or your particular preferences, but when you choose the latter, you’ll need a suitable heating system, and under-bench heating is ideal for a number of reasons. First, it makes excellent use of available space to provide radiant heat that surrounds crops.

It also promotes the movement of air as heat circulates and rises, helping to reduce excess humidity that could harm crops. This efficient system can not only reduce fuel costs by up to 10%, but it warms the medium and root zone before rising to heat the crops and the air above, creating ideal growing conditions.

Firebox Boiler

It’s hard to imagine more impactful commercial greenhouse heating solutions than boilers that offer reliable operation and cost-efficiency. Firebox boilers, in particular deliver incredible heating capacity paired with a compact design that will fit into spaces alternative options of similar capacity simply won’t.

This heating system provides quality design and lasting function, along with low-cost replacement parts and equipment that’s easy to clean and maintain. Available in gas, oil, or multi-fuel burners for your convenience, this type of boiler system provides the flexibility to meet a variety of heating needs with efficient operation that will suit any number of greenhouse layouts.

Fire Tube Boiler

While fire tube boilers offer neither the most compact structure nor the highest efficiency operation, they will meet your heating needs with aplomb, thanks to high capacity heat output. Even so, they are still relatively compact and cost-effective, compared to some other heating methods.

This high mass pressure vessel transfers heat to water through the walls of small diameter tubes, and because of the size of the unit, these vessels can hold a lot of water for heating purposes. You’re sure to appreciate the ease of cleaning, maintenance, and tube replacement, as well as high heat output that ensures a suitable environment for crops.

High Efficiency Condensing Boiler

As commercial greenhouse heating systems go, the high efficiency condensing boiler has a lot to offer, as it provides similar heating capacity to other boiler types, while taking up minimal space and delivering incredible efficiency. In addition to reducing energy costs with 99% thermal efficiency, which is even better than the 80% offered by a firebox boiler, you’ll enjoy a variable speed boiler pump that delivers incredible control that lesser boilers are not known for.

In addition, this compact, lightweight unit frees up space that you can use to maximize growing space, and the intuitive and appealing color touch display offers easy control over your heating system. While you will pay more up-front for this heating option, you’ll recoup costs and more in the long-term, thanks to high efficiency, reliable operation, and a system that offers lasting performance.

Carbon Dioxide (CO?) Dosing

One of the benefits of using a gas boiler to heat your greenhouse is that it creates carbon dioxide-rich flue gasses. For most businesses, this is not a boon, but plants require CO? for survival, and in an enclosed environment like a greenhouse, they can have trouble getting enough.

Adding a carbon dioxide condenser to your heating system can not only benefit your crops by allowing you to dose the environment with needed CO?, but this equipment can significantly increase your boiler efficiency, saving you money even as it improves plant health. Best of all, this component can easily be included as part of your larger heating system design.

Condensers

Boilers are among the most common commercial greenhouse heating solutions, but they aren’t without their challenges. While they certainly provide abundant heating capacity, and many advanced models are designed with features that improve efficiency and offer compact sizing, they can still suffer waste that impacts your bottom line.

The most effective solution is a flue gas condenser that diverts flue gases that might otherwise be wasted and uses them for added heating. If, like many greenhouse setups, you rely on multiple boilers to regulate interior temperatures, you’ll surely appreciate a combi-condenser that works with several boilers at once.

Expansion Systems

Any time water is heated, it expands, and if your greenhouse relies on a heated water system for interior temperature regulation, you have to make sure that you have a means of managing expanding water volume. This entails an expansion system capable of managing the high temperature and pressure inherent to heated water equipment, as well as the added volume produced.

You’ll need an open or closed tank system that includes an expansion/compression tank suitably sized and safeguarded for your needs. Your tank must meet ASME Code standards for safety and performance, and it is imperative that you choose a tank system that meets your unique requirements in terms of size and capability.

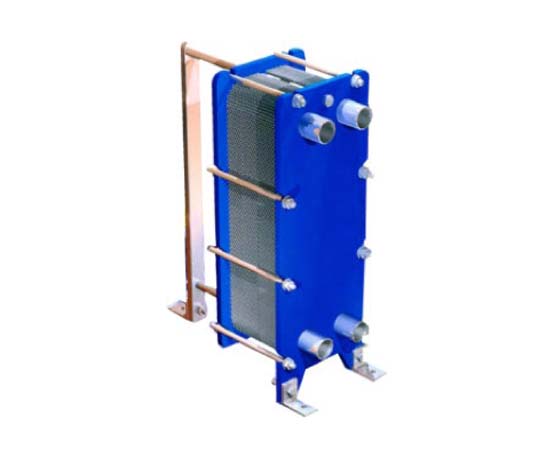

Heat Exchangers

Greenhouse operations are set up in a wide variety of ways, and therefor have diverse needs when it comes to heating and water use. While commercial greenhouse heating systems that include boilers are common, it’s also fairly normal to need a water supply that’s separate from your boiler system, and this is where heat exchangers come in handy.

Perhaps you want to heat growing pools or irrigate with water that hasn’t been heated. Maybe you need a portable hot water source. Heat exchangers can provide the solutions you seek in these and other common scenarios. There are three main types of heat exchangers: brazed plate, plate and frame, and shell and tube. Each has different features and benefits, so you’ll want to explore your options before choosing the one that’s right for your operation.

Pipe Insulation

Your greenhouse heating system may consist of a variety of pipes used to carry heat throughout your facility, some of them larger than others. Unfortunately, uninsulated pipes can constitute significant waste as heated water is transported from place to place. The larger the pipe and the higher the temperature, the more heat loss you’re likely to experience.

Pipe insulation is a must if you want to reduce heat loss, wasted energy, and unnecessary expense. With a 2-2.5-inch aluminum jacket, complete with moisture barrier to keep insulating materials dry, you’ll not only minimize heat loss, but the aluminum will actually reflect light in the environment, to the further benefit of crops.